Manufacture and sale of Hydropneu-Squeezer-System SQS

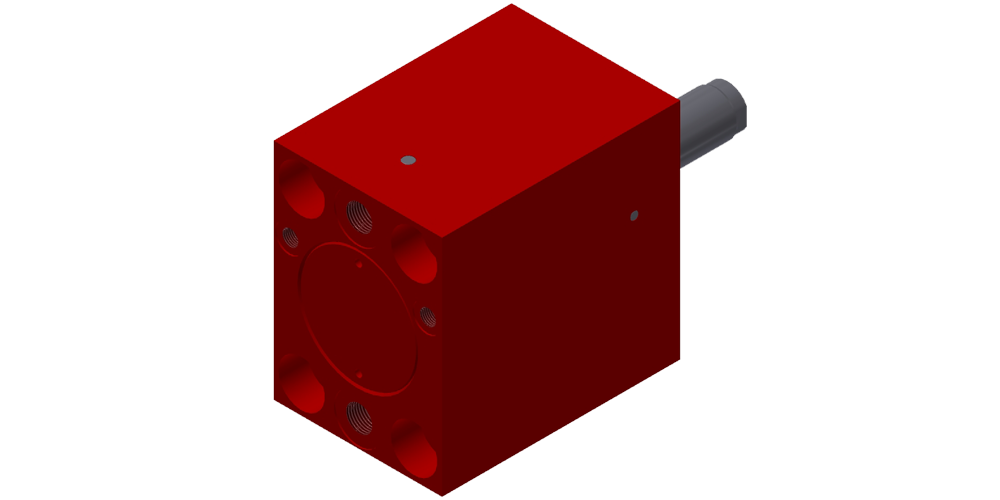

Hydropneu-Squeezer-System SQS

- Compact design

- High temperature resistance through active cooling

- Evaluation of the cylinder position with electronic components not susceptible to interference in the central mold.

- The new Hydropneu-Squeezer-System is optimally adapted to the needs of the die casting for this particular application.

- The solidifying material is compressed through squeezing to obtain void-free components with a high load capacity. Consequently, this process must take place at a certain point and thus the mounting position is absolutely predetermined.

- In general, the available mounting space is very tight. The high temperatures that often prevail at these positions of the die casting molds, when using an uncooled hydraulic cylinder, result in a very short life of the seals.

- Due to the limited space and also the high temperatures it is usually hardly possible to evaluate the driven path, which in particular would be desirable for the casting results.

Hydropneu-Squeezer-System SQS

Datasheet Hydropneu-Squeezer-System SQS

You will be redirected to the global GVCN 3Ds.

If it is an existing cylinder replacement, please send a request to hps@hpsinternational.com or contact your sales representative.

If it is an existing cylinder replacement, please send a request to hps@hpsinternational.com or contact your sales representative.